Hi All!

Just received my new NOE 9mm Truncated Cone mold, and cast up some new to me boolits. I had been using Lee 356-124-TC prior to this.

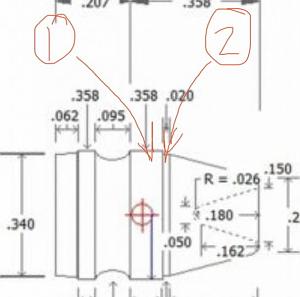

My COL for the TC, that works super sweet, for my Sig P938, lands the case mouth, a hair shy of the beginning of the taper, of the TC. With this mold, that actually works out, right on the forward leading edge, of the forward band.

I’ll need to adjust my COL to put that taper crimp, in a functional spot.

Assuming that either position will work for my Sig… should I be trying to get the crimp, in the band ( spot 1 on the drawing) or should I be aiming for that .020” sliver ( spot 2 in drawing) between band and taper ?

Thanks for any input!

|

|

|

Reply With Quote

Reply With Quote