Hey all,

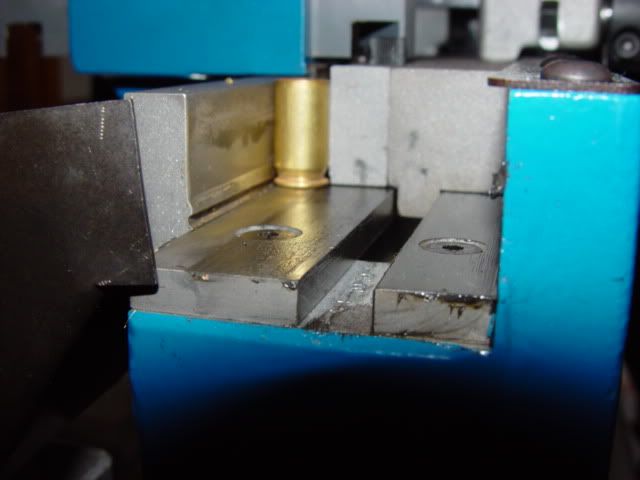

Have some range pickups that have some typical buldges from unsupported chambers. Havent ever had many issues with .45acp. But these 40 brass thru my lyman sizer die are not going so smooth. It is actually removing some brass at the very base. Unsure how to solve this or if there is even a solution. Would like to save as much brass as possible. Tried using a little case lube to see if that would help with minimal results.

Thanks for any insight,

Aaron

|

|

|

Reply With Quote

Reply With Quote

W.R.Buchanan

W.R.Buchanan