Folks,

I picked up a used Ruger Super RedHawk in 454 Casull recently. It is a nice gun, very heavily built.

I loaded it up with 2 loads:

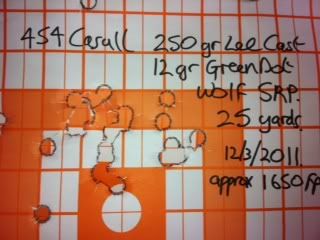

1) Lee 250 grain cast bullet tumble lubed with Alox/JPW, unsized as cast (nominally .452 diameter) + 12 grains Green Dot + Wolf SR primer. I showed chrony results of 1650 fps but I am not sure if that is accurate or not.

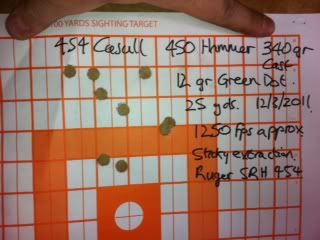

2) Lee 340 grain Hammer group buy mold (drops .460) lubed and sized to .454 + 12 grains Green Dot + Wolf SR primer. Chronys about 1250 fps.

I found I had to seat both bullets quite deep in the case (top of bullet about 1/8 th of an inch above the brass rim) to get it to seat properly in the Ruger 454 chamber. In hindsight, there may have been crud built up in the chamber from the previous owner shooting 45 LC that was causing the problem.

The first load shot as follows:

And second load shot as follows:

Both were off sandbags at 25 yards.

The first load required a slight tap on the ejector rod with a wooden mallet to drop the brass. The second load requied significant force to get the brass out of the chamber, in fact more force than I was comfortable with.

I used previously-fired brass, slightly dirty but not excessively so.

Any ideas as to why the brass was so sticky? These loads are not particularly hot for a 454 Casull gun. There were no pressure signs on the primers (no flattened edges or punctured primers) that I could see.

Advice/solutions would be much appreciated.

|

|

|

Reply With Quote

Reply With Quote