I had two issues with my T7 Turret: 1) Loading .45 ACP result in lead shavings inside the seater die and the crimper die. Looking closer, the lead shavings weíre all on one half of the inside diameter of the die. 2) Loading .40 S&W resulted in a small, but unacceptable, occurrence rate where the bullet seated at a large angle to the case. The case was bulged on one side, looking pregnant.

*

I had RCBS & Hornady shell holders for both calibers, and all four combinations had issues with the case being eccentric to the die. Looking closely, I could even see the case tilt as it collided with one side of the die. So I sent the Turret into Redding. They told me the Turret Press was aligned properly, so it must be my shell holders (all 4 of them). They sent me one shell holder (and a Redding baseball cap) in .45 ACP and it does perform better.

*

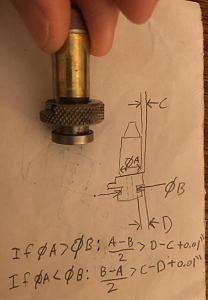

So I decided I needed a way to determine which of my shell holders were bad/good. What I came up with is shown in the image below - if the appropriate calculation holds true, then the shell holder is good. The reason why I added 0.01Ē is to provide extra clearance, so thereís fore-aft wiggle room, and because all dimensions needed to truly confirm case-to-die alignment cannot be measured with calipers.

*

Collecting these measurements on my RCBS & Hornady shell holders confirms that I cannot possibly push a case deep enough into a shell holder in order to get the case concentric with a die (for all 4 of them). Now I need to go buy a Redding .40 S&W shell holder.

*

Note: if the press ram has deep fore-aft clearance, then the 0.01Ē buffer Iím using is not appropriate.

*

|

|

|

Reply With Quote

Reply With Quote

W.R.Buchanan

W.R.Buchanan