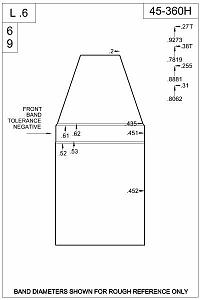

Well I've done a little shooting with the 400 grainer and it is not quite up to snuff either. Having issues with the meplat interfering with some part of the barrel extension. I got an improved design on the way. This time I ordered in 2 cavity only. Should be a little easier to run. Here is my new design in the Accurate Molds catalog.

Sooo, ran the calculations, and I think if I can get this baby up to 2000 FPS that's 3300 lb ft at the muzzle!

|

|

|

Reply With Quote

Reply With Quote