I hate to criticize any LEE product and I will start out by saying I have two of these inexpensive measures (bought together) and mine DO THROW ACCURATE CHARGES. (I have the best accuracy when I DO NOT double/tripple tap the lever on the up OR down stroke).

I just wish LEE offered something these $25.00 measures and my $250.00 Harrell ball bearing bench rest measure!

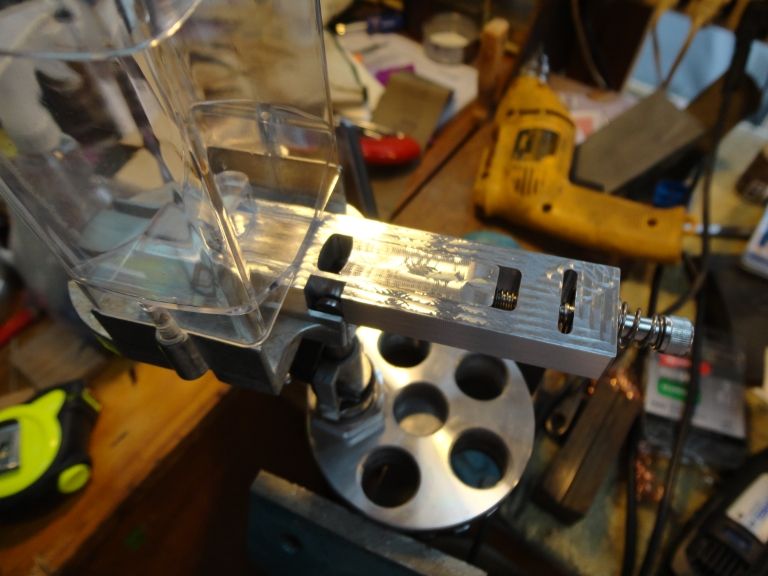

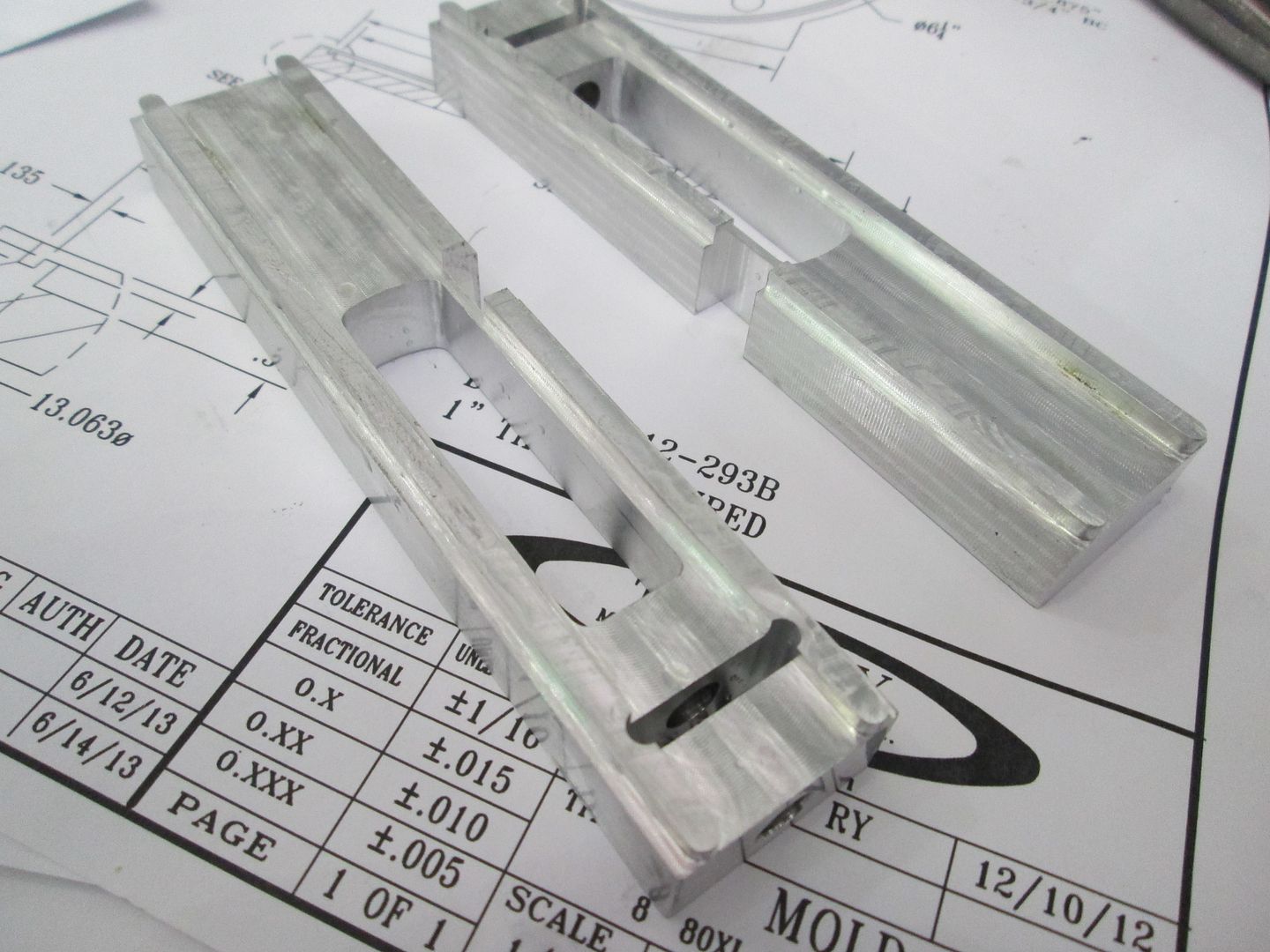

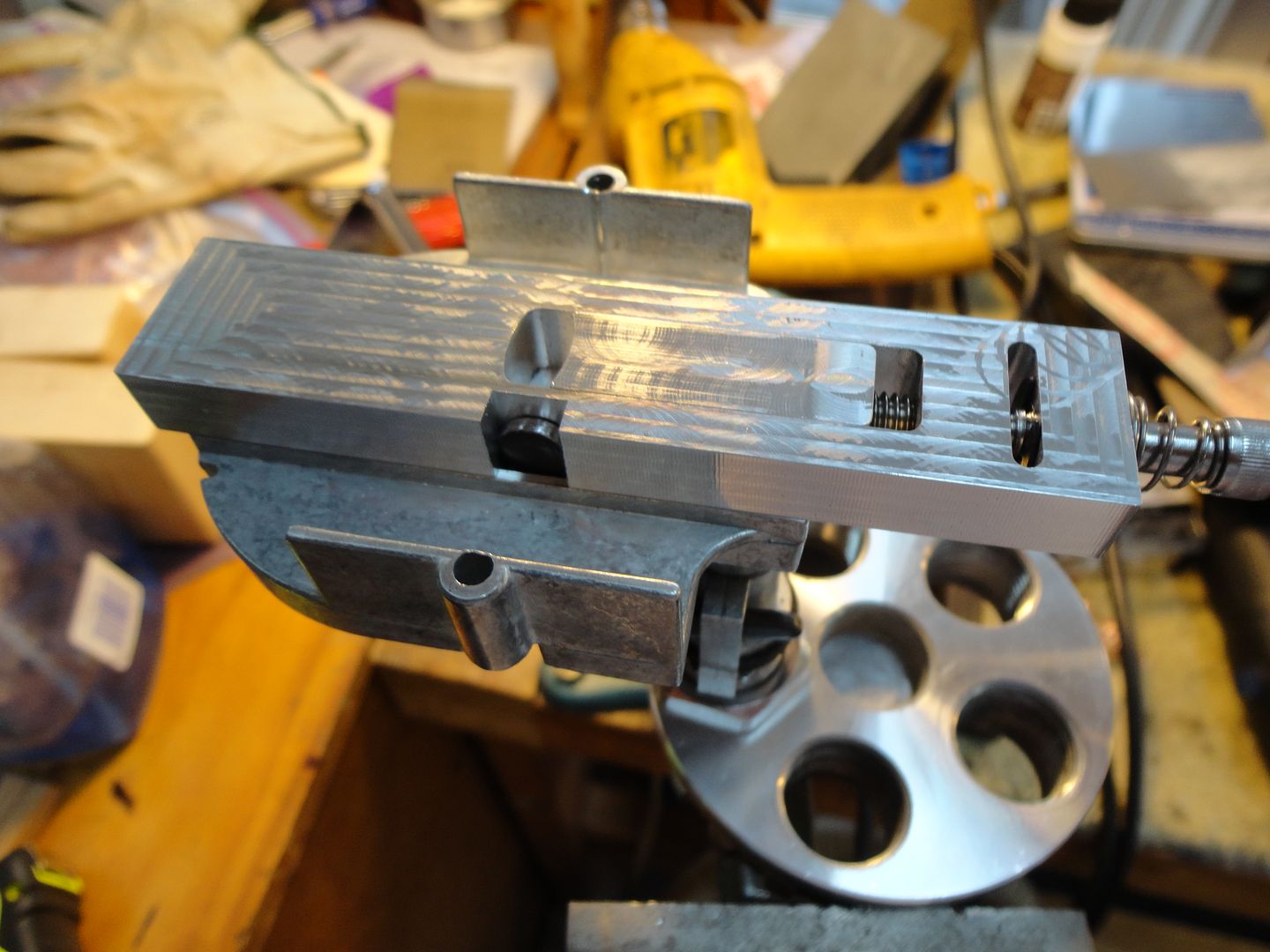

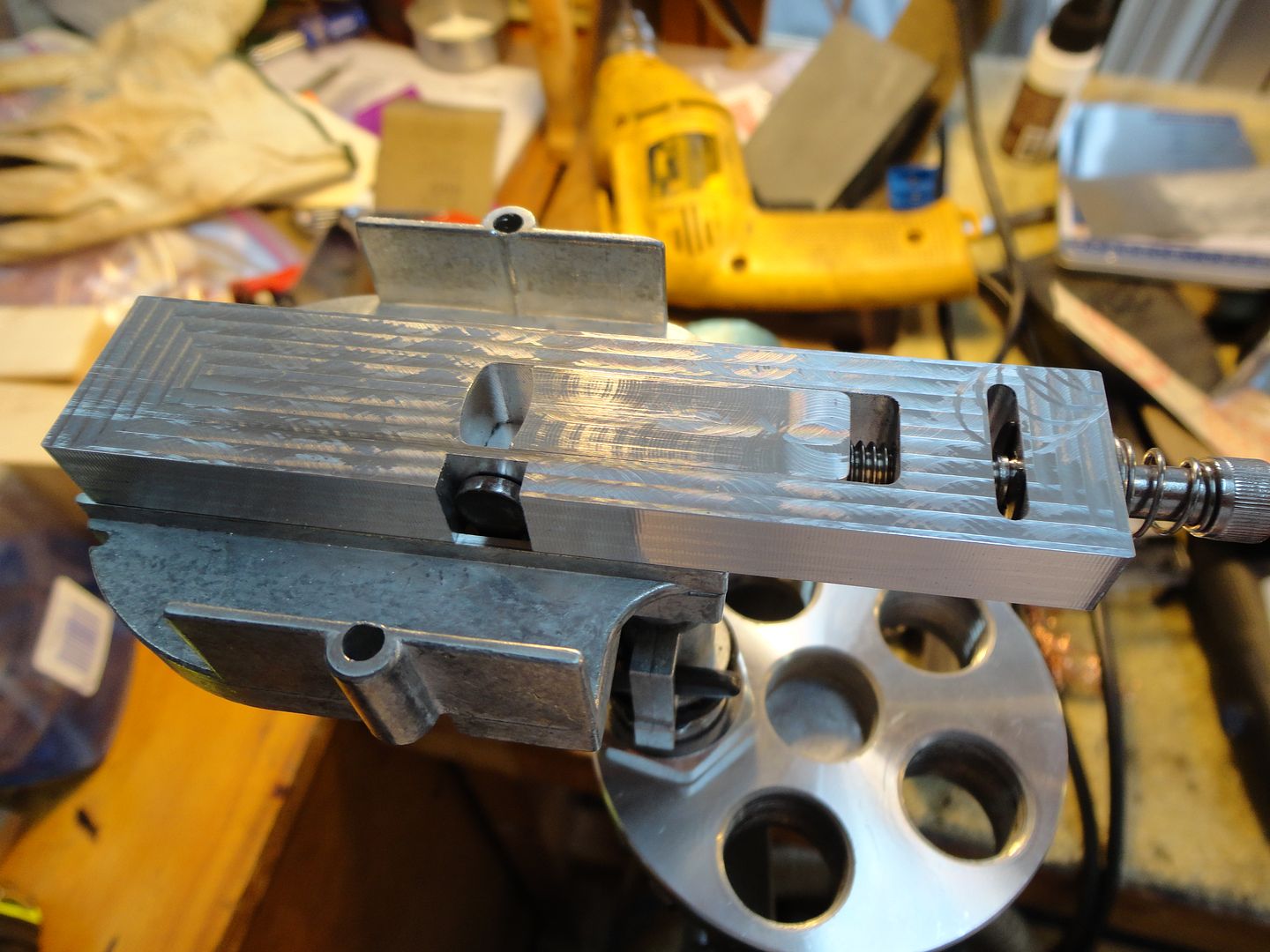

These little LEE measures are ackward and clumsy to use and they FEEL bad when rotating the cylinder. I've tried dusting the rotor with powdered graphite and running several hoppers of nice dirty Bullseye powder through the measure. I also backed off the tension screw 1/8 turn (please mark your screw/cylinder BEFORE dissembling the measure. MAYBE I feel a 10% improvement.

HAS anyone found a way to get these to turn smoothly, with lighter pressure on the operating lever??

For me, five $25.00 measures pre-set for my 5 favorite loads would be a lot more useful than one $125 metal powder measure. HELP!

|

|

|

Reply With Quote

Reply With Quote DougGuy

DougGuy